ZT Tooling & Molding is strongly committed to quality and quality control systems are accredited to ISO 9001.The document control system goes through all the production & quality control inspection processes.We have independent quality control department who controls every quality inspection step from incoming material, production process, assembly, packing, as well as cargo shipment.We have established quality evaluation program for each process to assure our customer the best quality products and most professional service.

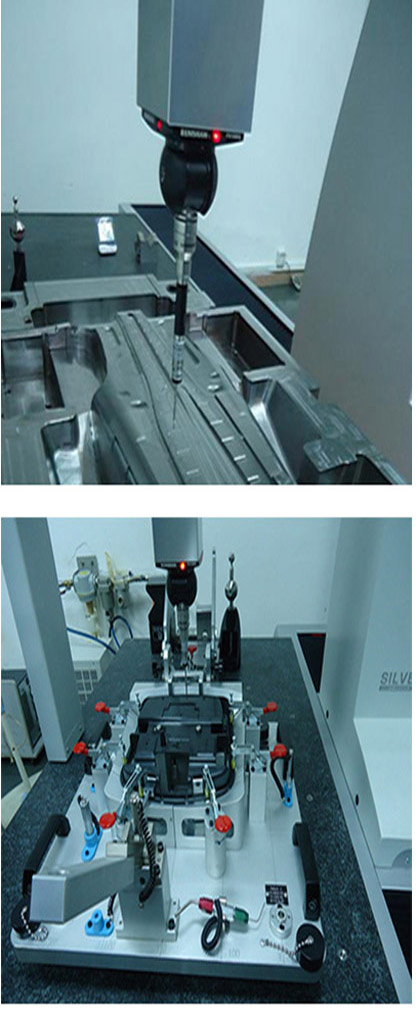

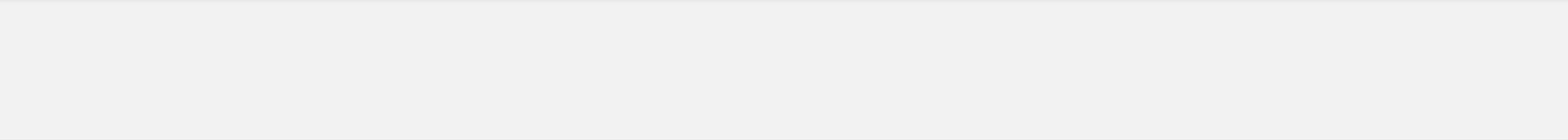

Advanced Inspection Instrument

Since its foundation, ZT Tooling & Molding has exerted great efforts in quality control to ensure the good quality of plastic injection tooling and molding parts.Being committed to the goal of providing only quality molds,we introduced advanced 3-coordinate measuring instrument, high -definition optic projector, precision detector,digital 3D laser scanner imported from UK, etc. Comprehensive quality management measures have been taken during the whole processes of molds production.

A Complete Quality Control System

1,This system covers all processes from the mold designing to the final delivery. All software adopted by each department should be the latest updated and controlled version;

2,An independent quality assurance department implements the quality control system and monitors each link;

3,Trainings on quality control and related skills have been provided to our stuff to ensure the smooth implement of this system

Continuous Quality Improvement

Since quality improvement is a never ending process, ZT Tooling & Molding has adopted Lean Manufacturing principles and has utilized these principles through the use of cross functional teams working on every improments,

1,Monthly quality defect analysis as well as regular meeting held by each depart helps promote our quality control work and ensures better quality of tools and molding parts we produced.

2,By the project management, we can optimize the allocation of advantageous resources and concentrate on major quality problems,

preventing quality defects in an efficient way;

Home

Home

Capabilities

Capabilities

Cases

Cases

Contacts

Contacts