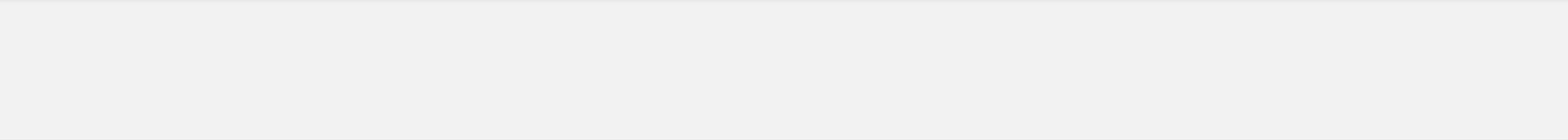

Moldflow analysis (mold simulation software) uses a computer program to analyze and predict plastic flow and cooling during all phases of the injection molding process. Moldflow ensures part design elements — wall thickness, draft, gate locations, geometries, etc. — are appropriate for the component’s process, tooling, and aesthetics. ZT Tooling & Molding does full Moldflow simulation in house.

Here are some of the benefits you can expect from us:

Optimized gate locations: In the past, gates (those areas that control plastic flow to the cavities) were made smaller initially and then re-machined after sampling the part—a costly and time-consuming step.

• Mold cavities that are filled uniformly and consistently

• Ability to find visual defects: Air traps and sink marks are discovered and eliminated up front.

• Wall thickness issues are resolved

• Weaknesses in design can be corrected

• Various materials can be evaluated before production

• Improvements to the manufacturability of the part can be made

• The time it takes to get your parts to market is reduced

Home

Home

Capabilities

Capabilities

Cases

Cases

Contacts

Contacts