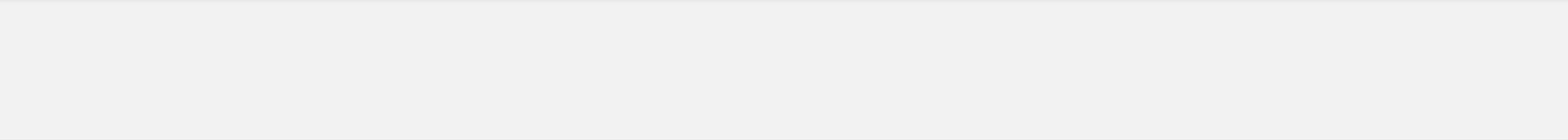

Generally speaking, Design for Manufacturability (DFM) — or Design for Manufacturing — is the process of consciously and proactively designing products to optimize all facets of manufacturing.

DFM methodology aligns engineering and production in the design phase, ensuring cost and time efficiencies, superior quality, regulatory compliance, and end-user satisfaction. Problems are identified and addressed early in the product development process, preventing costly issues that could impact manufacturability: raw materials selection, tolerances, and secondary processing.

Within injection molding, successfully executing DFM for complex applications requires considerable technical expertise. This magnifies the importance of partnering with an experienced molder.

An experienced molder know DFM analysis uncovers opportunities for improving manufacturability, increasing speed to market, and reducing costs. One of the most obvious ways to reduce costs is to reduce changes needed after building the tool. No one wants to incur the expense — or the potential for significant project timeline delays — caused by retooling. DFM analysis gives injection molding engineers project insights that save manufacturers time and money by identifying potential part moldability issues and solutions during the design phase.

Proper part analysis and any part design modifications that result from that analysis, help simplify tooling, reduce the molding cycle, and reduce costs. Minimizing changes after tool build is all about finding practical solutions to project impediments that could jeopardize successful outcomes.

Our team has over 100 years of combined experience, and each team member has extensive knowledge and experience in all aspects of tools,Not only can we solve the problem, but the most important thing is that we can avoid the problem in advance.

Home

Home

Capabilities

Capabilities

Cases

Cases

Contacts

Contacts