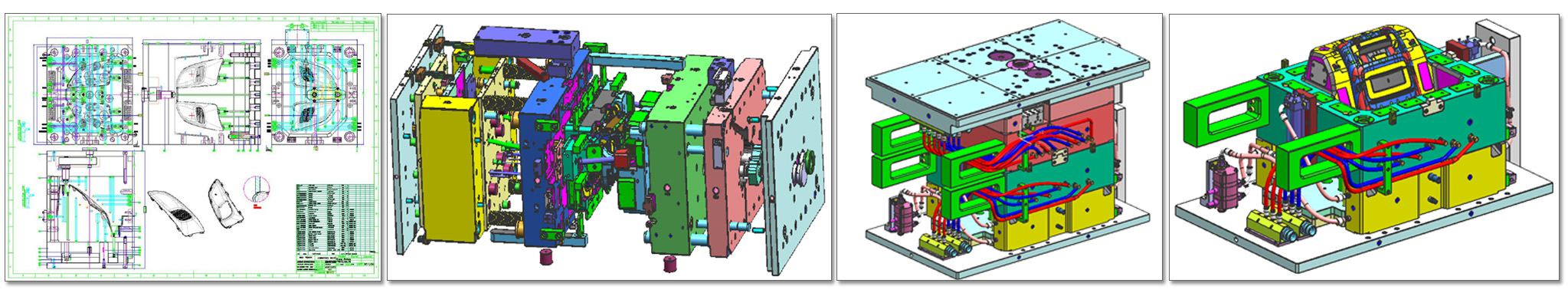

Plastic Injection molding is a precise manufacturing process where molten resins are injected in a predesigned mold. As the part cools and hardens, it is then taken out of the mold for adding finishing touches. Tooling and mold design are an important aspect of injection molding.

Mold designing along with the various components involved (commonly known as tooling) is a very complex process that requires high levels of technical expertise. Additionally, the process calls for engineering know-how to produce plastic parts with accurate dimensions and design features.

Tooling engineers and mold designers need to work out accurate calculations on gate sizing, (to get proper filling) and the best techniques that produce tooling durability.

Additionally, it is important to carefully design the system of runners and gates to get an even distribution of plastic resin through the mold. It is also important to consider proper placement of cooling channels along the mold walls to create a homogenous product and eliminate defects that are common in plastic injection molding.

Complex plastic parts require complex mold designs. Various components need to be added to the mold for this purpose. These could include features like rotating devices, hydraulic cylinders, multi-form slides, floating plates, etc.

ZT Tooling & Molding design team has over 100 years of combined experience, and each team member has extensive knowledge and experience in all aspects of tools,Not only can we solve the problem, but the most important thing is that.

Home

Home

Capabilities

Capabilities

Cases

Cases

Contacts

Contacts